Photography: STAMERS KONTOR

Tailorcrete

TailorCrete is a 4-year research project under EUs FP7 with 14 partners looking into integrating robotics and automation to concrete construction processes. The purpose is to develop new industrial technologies for complex concrete structures at mass customized prices.

Even though concrete is a fluid material that could take any shape; it is not often used for building complex geometries. Processes that require hand labor restrict complex geometries to big and expensive projects. But putting aesthetics aside is it possible to find reasons why architecture should employ complex geometries? Increased awareness of environmental responsibilities and worldwide economic downturn, ‘Non-Standard’ or ‘Optimized’ design and construction is slowly being recognized as a critical solution. Instead of standardization, optimization of designs and procedures for better efficiency and performance is becoming the new goal. Optimization of designs based on a variety of criteria from acoustics to load-carrying capacity, leads to complexity in form.

Current processes used for building complex geometries are inefficient. Typically the concrete is poured into handmade formwork. Precast concrete on the other hand is usually restricted with orthogonal forms. However, the advancements in robotics and software promise a more complex formal vocabulary.

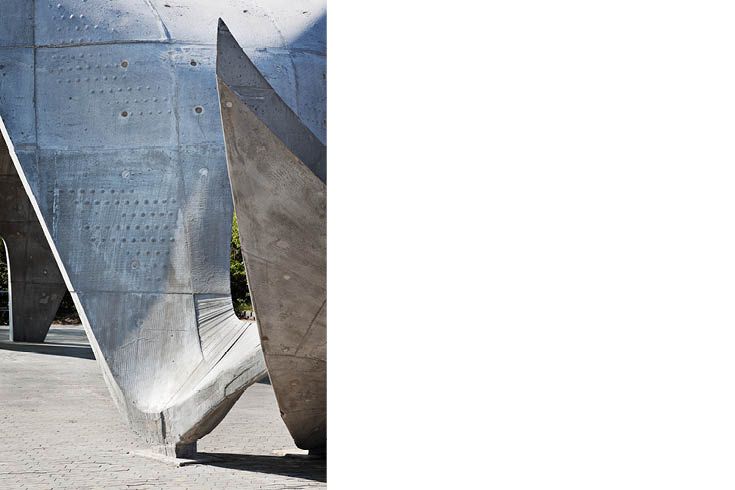

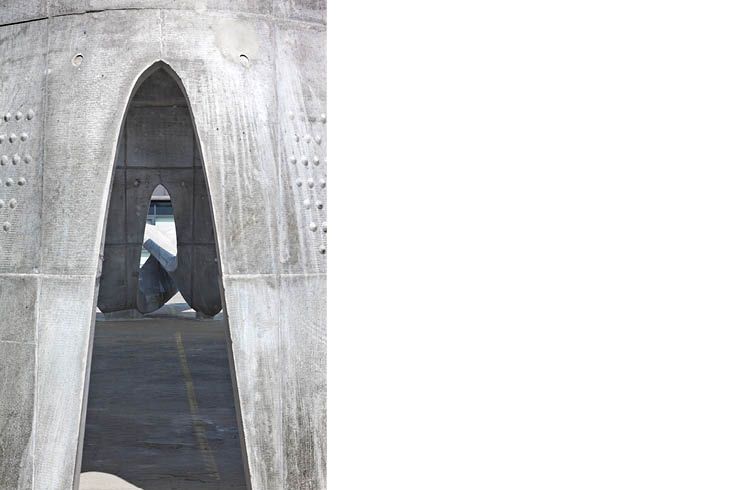

TailorCrete aims to transform construction into a knowledge-based industry. Led by Danish Technology Institute, the research consortium consists of Bekaert, Chalmers University of Technology, Czech Technical University, DesignToProduction, Dragados, ETH Zürich, Gibotech, Grace, MT Højgaard, Paschal, Superpool, Unicon, Syddansk Universitet. The Full Scale Demonstrator (FSD) designed by Superpool is optimized in its structural performance by ‘folding’ the concrete plate. Ranging from 15 cm to 25 cm in thickness the structure spans 23 m at 6.5 m height. FSD incorporates technology developed during TailorCrete in fabrication based design tools, formwork, traditional and fiber reinforcement, digital fabrication using automation and robot technology, and concrete mixtures.

The TailorCrete project has been highlighted as a "Success Story" by the EU Commision.

For more information visit www.tailorcrete.com

CONSORTIUM

Project Leader:

Danish Technology Institute

Partners

Bekaert, Chalmers, Czech Technical University, DesignToProduction, Dragados, ETH Zürich, Gibotech, Grace, MT Højgaard, Paschal, Superpool, Unicon, University of Southern Denmark

Team:

Selva Gürdoğan, Gregers Tang Thomsen, Marta Marszal, Nikitas Gkavogiannis, Matthias Poen, Asbjørn Lund, Benjamin Bosse, Aron Bohmann, Mustafa Bulgur, Simon Oberhofer, Nandini Oehlmann, Philip Stapel, Dicle Uzunyayla

Type: Research Project

Client: EU Commission

Status: Completed